Pexco

PexcoRequest A Quote

Alpharetta, GAAt Pexco, we take pride in being a leading force in the design and manufacture of injection molded plastics that serve a wide range of industries. We have built our reputation on delivering high-quality plastic components that meet the most demanding requirements, whether they are for industrial applications, consumer products, or specialized markets. Our strength lies in combining engineering expertise with advanced manufacturing processes to create solutions that are both reliable and cost-effective. We offer complete support throughout the production cycle, from concept development and design assistance to tooling, molding, and finishing. By working closely with our customers, we ensure that every component we produce meets exact specifications, whether it requires tight tolerances, complex geometries, or unique material properties. Our injection molding capabilities allow us to work with a broad spectrum of resins and additives, enabling us to customize performance attributes such as durability, chemical resistance, flexibility, and thermal stability. Beyond manufacturing, we provide value-added services such as assembly, prototyping, and secondary operations that help streamline supply chains and reduce lead times. Our team is skilled at optimizing designs for manufacturability, ensuring that our customers benefit from efficient production runs without sacrificing quality or performance. We view every project as a partnership, taking the time to understand our clients’ needs so that we can deliver solutions that not only meet their requirements but also enhance their competitive edge. Through innovation, technical expertise, and a commitment to precision, we continue to expand our capabilities and grow with the evolving demands of the industries we serve. At Pexco, we see ourselves not just as a plastics manufacturer, but as a trusted partner dedicated to creating products that drive success for our customers.

More Plastic Molding Manufacturers

Additional Categories: Dust Collector

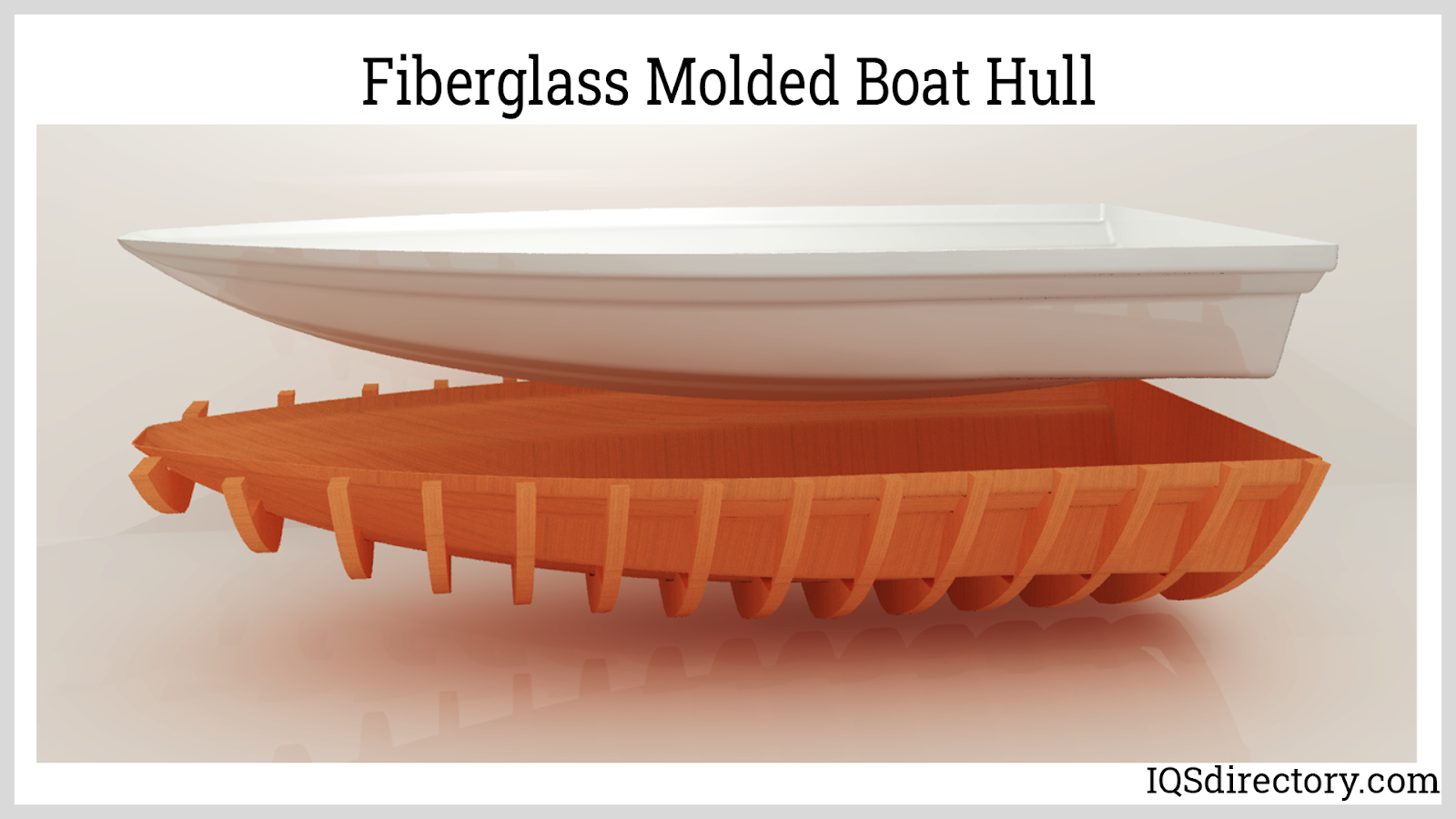

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

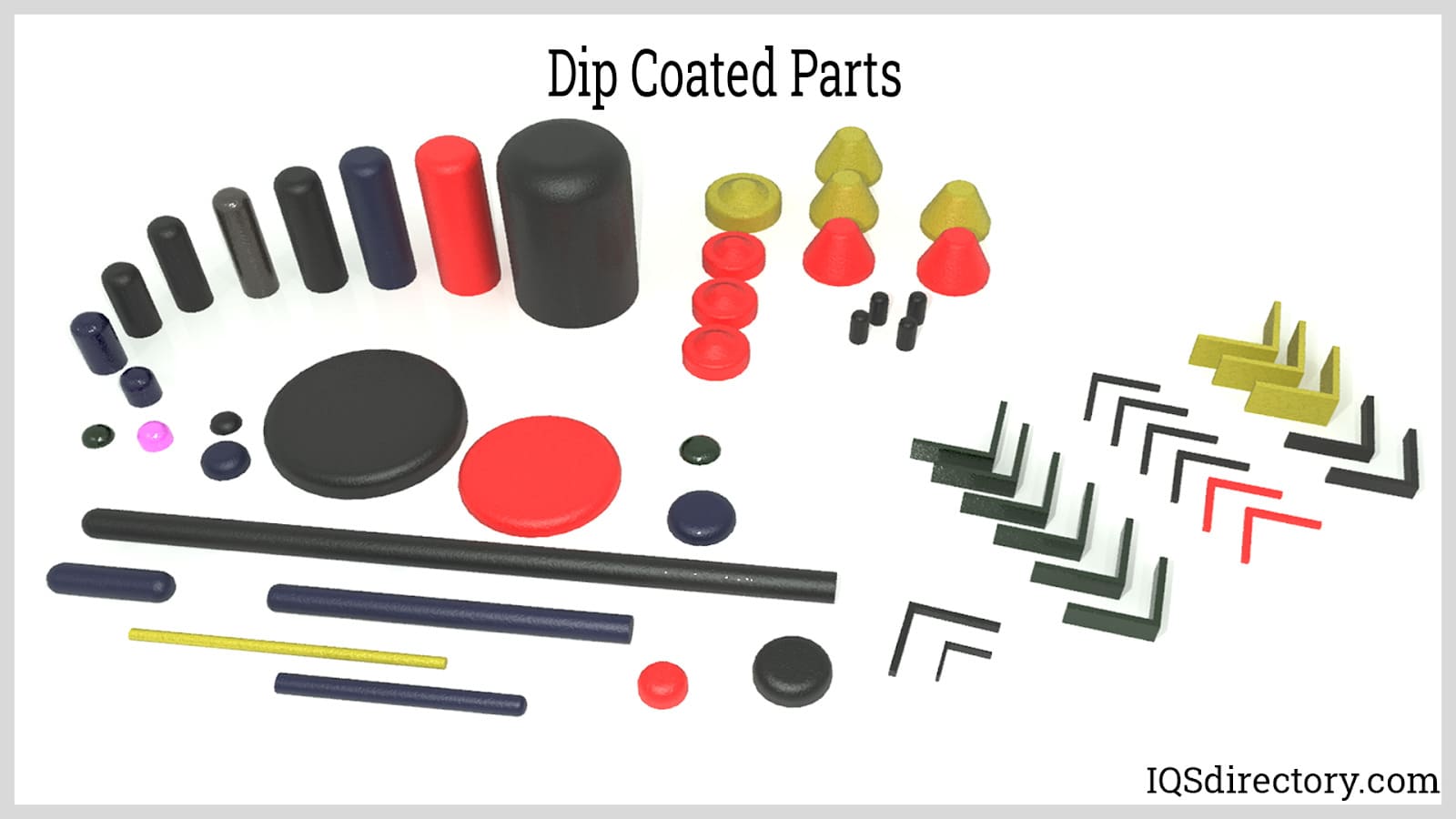

Plastic Blow Molding Plastic Dip Molding

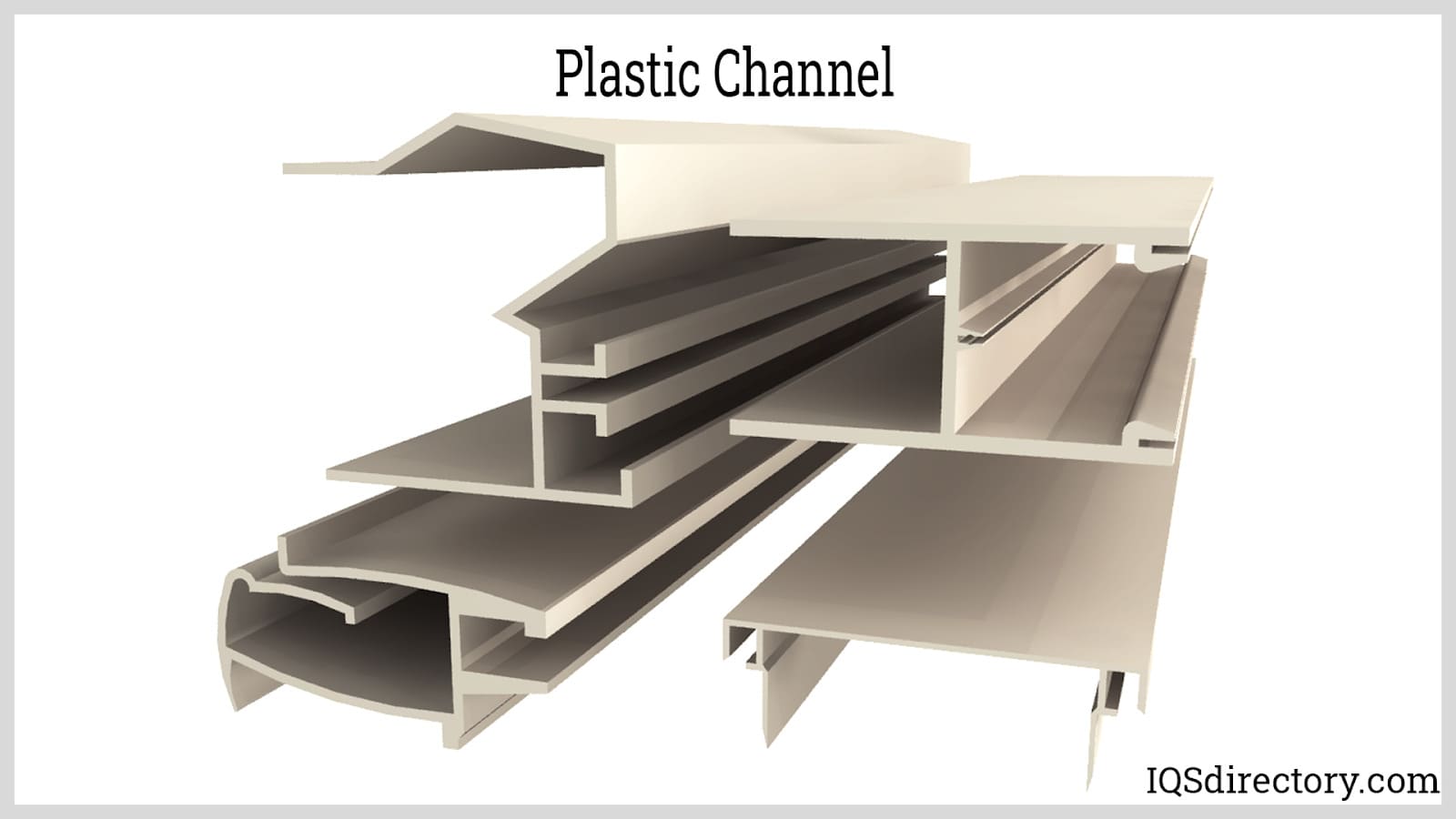

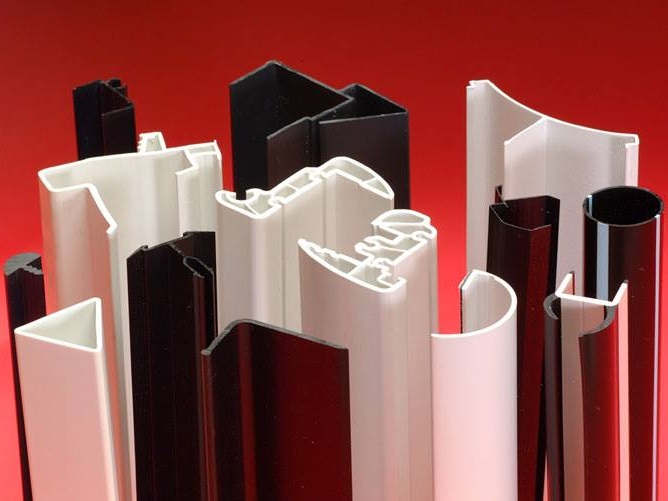

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services