P.Q.D. International, Inc.

P.Q.D. International, Inc.Request A Quote

Sherman, TXAt P.Q.D. International, Inc., we are at the forefront of the injection molded plastics industry, specializing in delivering high-quality, precision-engineered solutions for a wide range of applications. Our advanced injection molding technology allows us to produce intricate and durable plastic components that meet the most demanding specifications. From initial concept through to final production, we leverage our state-of-the-art facilities and skilled team to ensure that every product we create embodies excellence and reliability. Our product portfolio is as diverse as the industries we serve. We manufacture everything from complex automotive parts and consumer goods to robust industrial components. Each product is designed with meticulous attention to detail, ensuring it not only meets but exceeds the stringent requirements of its intended application. Our ability to produce high volumes of consistent, high-quality parts makes us a preferred partner for clients looking for both precision and efficiency in their manufacturing processes. Our comprehensive services encompass every stage of the injection molding process. We start with in-depth consultations to understand our clients’ needs, followed by innovative design and prototyping to bring their ideas to life. Our production capabilities are geared towards delivering both small and large-scale runs with unparalleled accuracy and speed. Throughout the project lifecycle, we remain engaged with our clients, providing expert guidance and support to ensure their objectives are met seamlessly. Innovation drives our approach at P.Q.D. International, Inc. We are committed to exploring new technologies and materials to enhance our capabilities and stay ahead of industry trends. Our focus on continuous improvement enables us to offer cutting-edge solutions that not only meet current demands but anticipate future needs. Whether you are seeking high-performance components or reliable manufacturing solutions, we are dedicated to partnering with you to achieve outstanding results and drive success in your ventures.

More Plastic Molding Manufacturers

Additional Categories: Cnc Machining

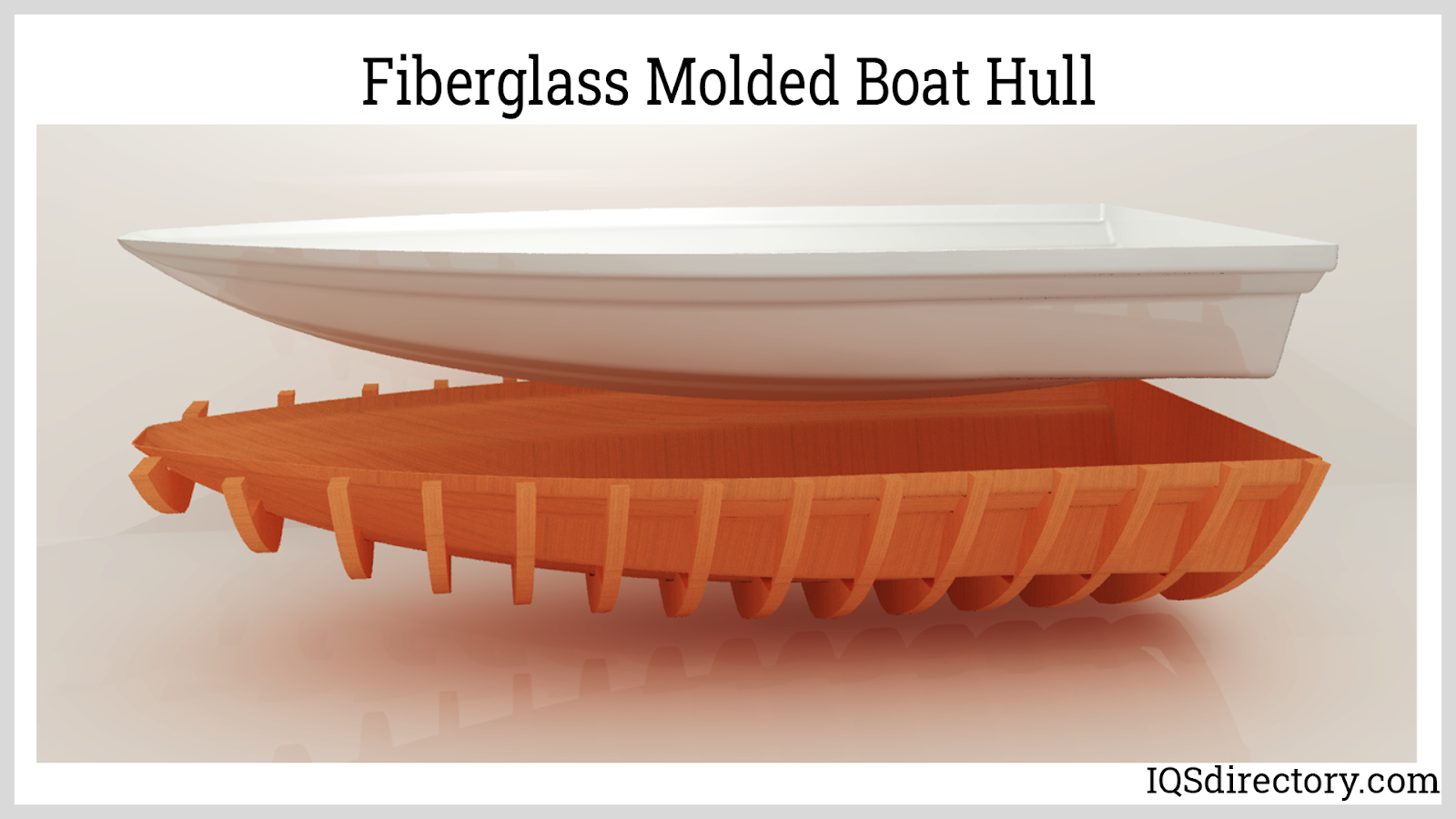

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

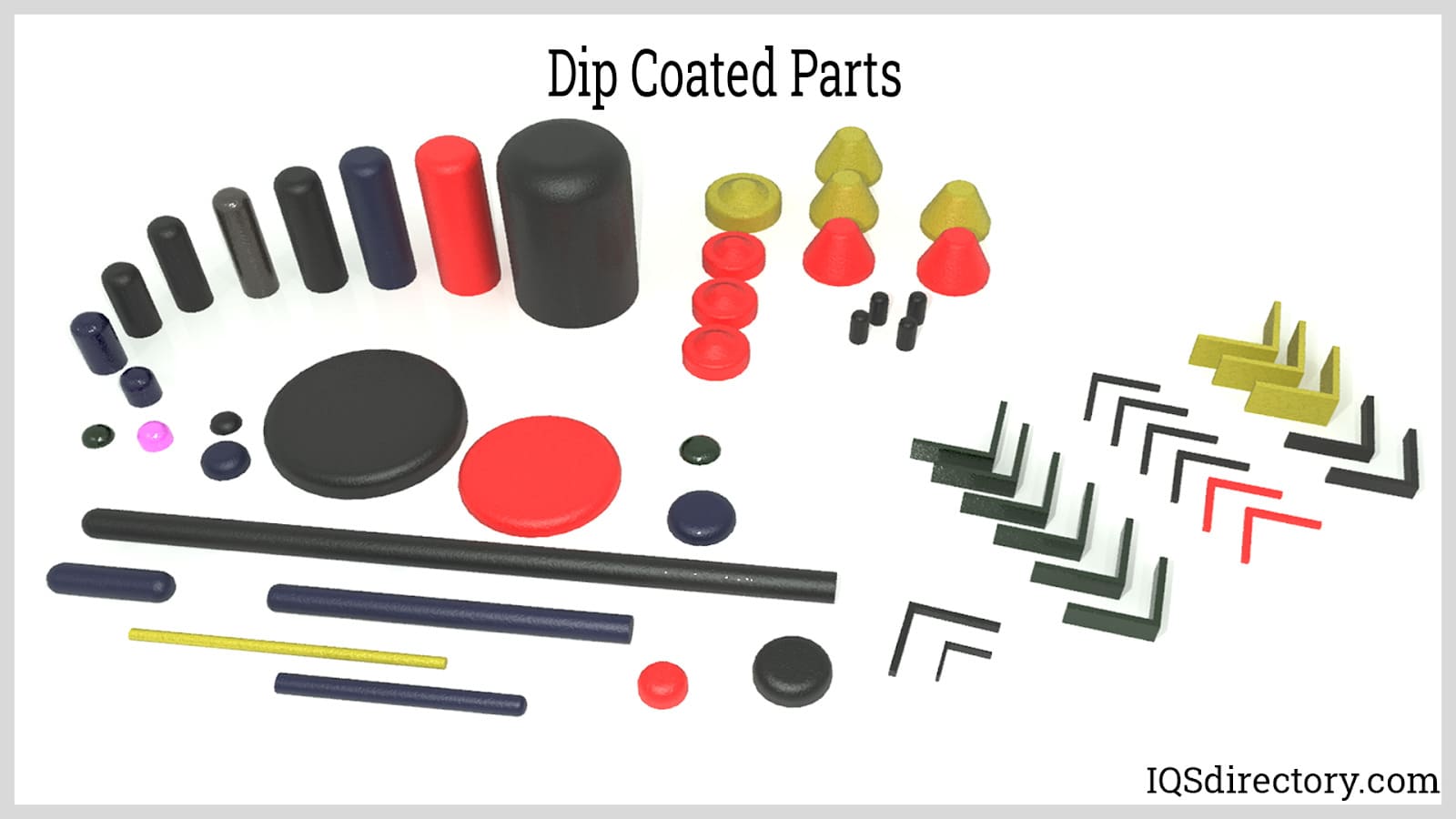

Plastic Blow Molding Plastic Dip Molding

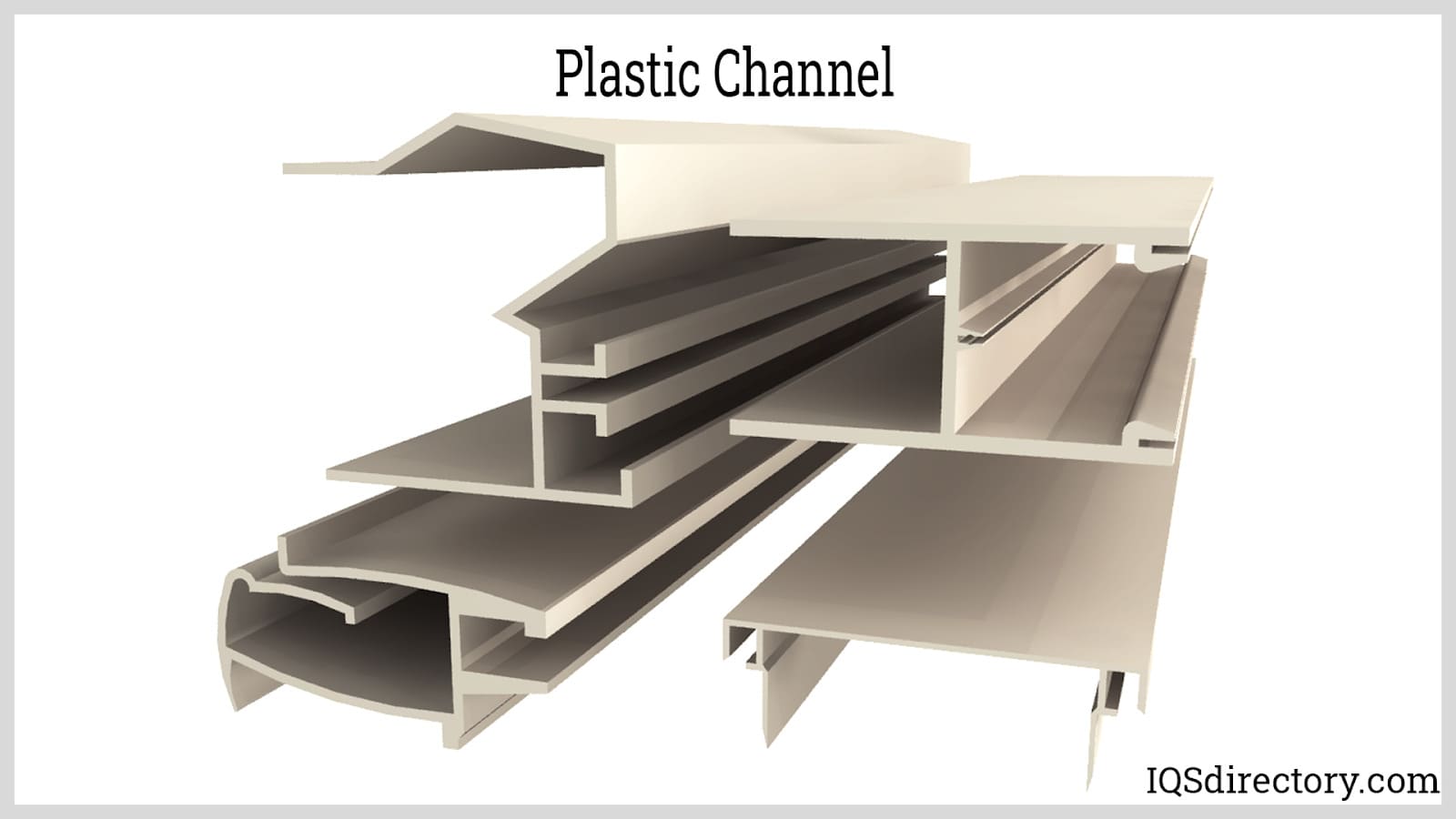

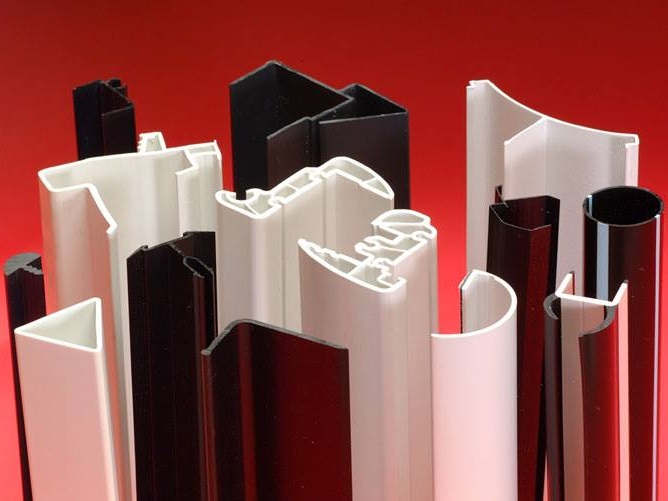

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services