Lomont Molding LLC

Lomont Molding LLCRequest A Quote

Mt. Pleasant, IA | 800-776-0380Lomont Molding is a leading manufacturer and supplier of injection molded plastics products, serving a variety of industries, including automotive, consumer goods, electronics, and healthcare. The company was founded in 1982 and has since established a reputation for producing high-quality products and providing excellent customer service. Lomont Molding offers a wide range of injection molding services, utilizing a variety of thermoplastics, including polycarbonate, ABS, nylon, and others. Their state-of-the-art manufacturing facilities are equipped with the latest technology, including advanced molding machines, robotics, and automated assembly systems, enabling the production of complex parts with high precision and consistency. The company's experienced team of engineers and technicians work closely with customers to provide design and engineering support, rapid prototyping, tooling, and finishing services to help bring products to market quickly and efficiently. Lomont Molding has a strong commitment to quality, and their comprehensive quality management system ensures that every product meets or exceeds customer requirements. They are certified to ISO 9001:2015 and IATF 16949:2016 quality standards. Lomont Molding's injection molded plastics products are used in a wide range of applications, including automotive components, consumer electronics, and medical devices. Their products are known for their durability, strength, and high-performance characteristics, which make them ideal for use in demanding applications. In addition to injection molding, Lomont Molding also offers other plastic fabrication services such as blow molding, rotational molding, and thermoforming. This enables them to provide a comprehensive range of plastic manufacturing solutions to their customers. Overall, Lomont Molding is a trusted partner for businesses looking for high-quality injection molded plastics products and services. With their state-of-the-art manufacturing facilities, experienced team of professionals, and commitment to quality, they are well-positioned to help their customers succeed in today's competitive marketplace.

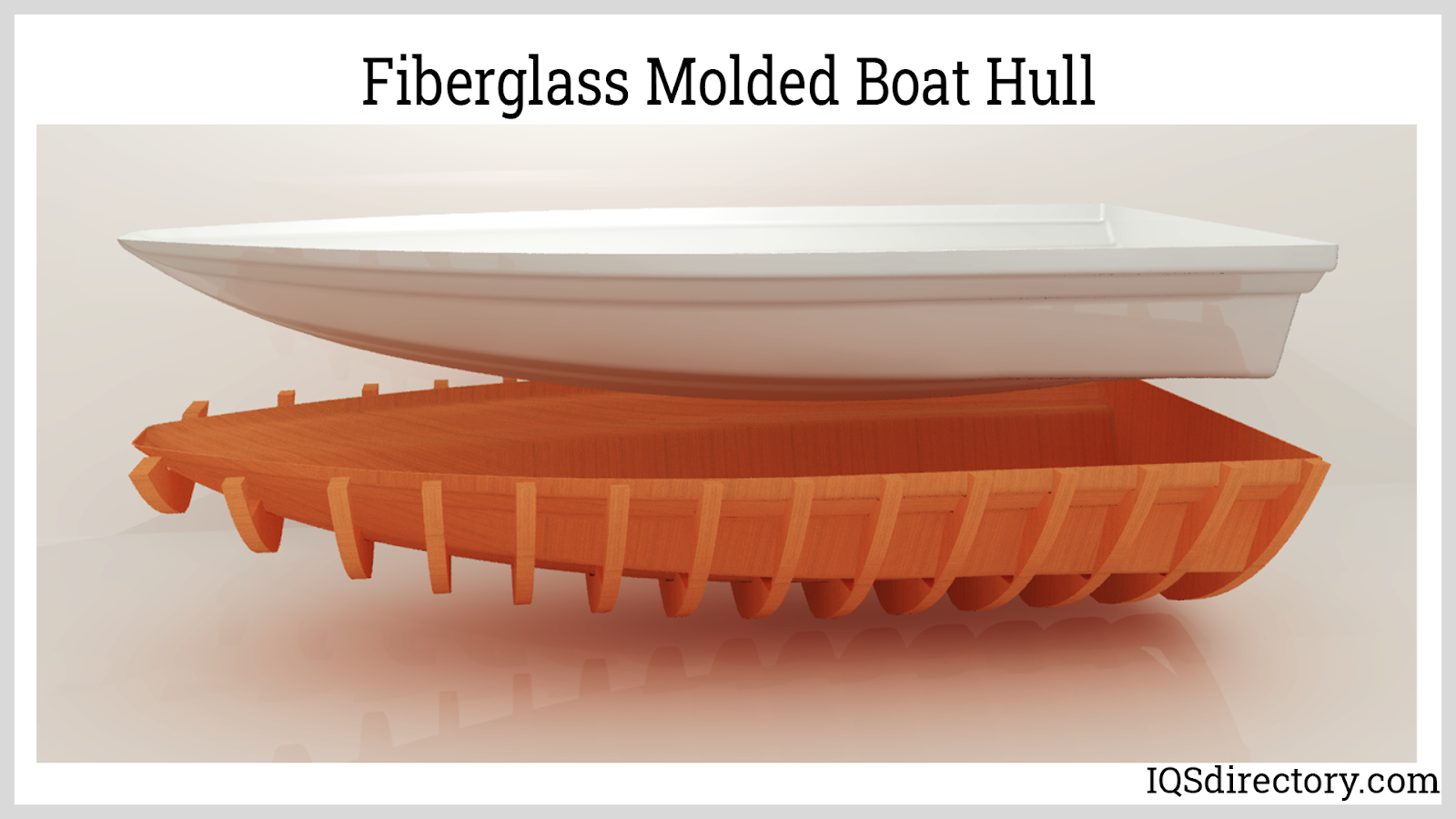

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

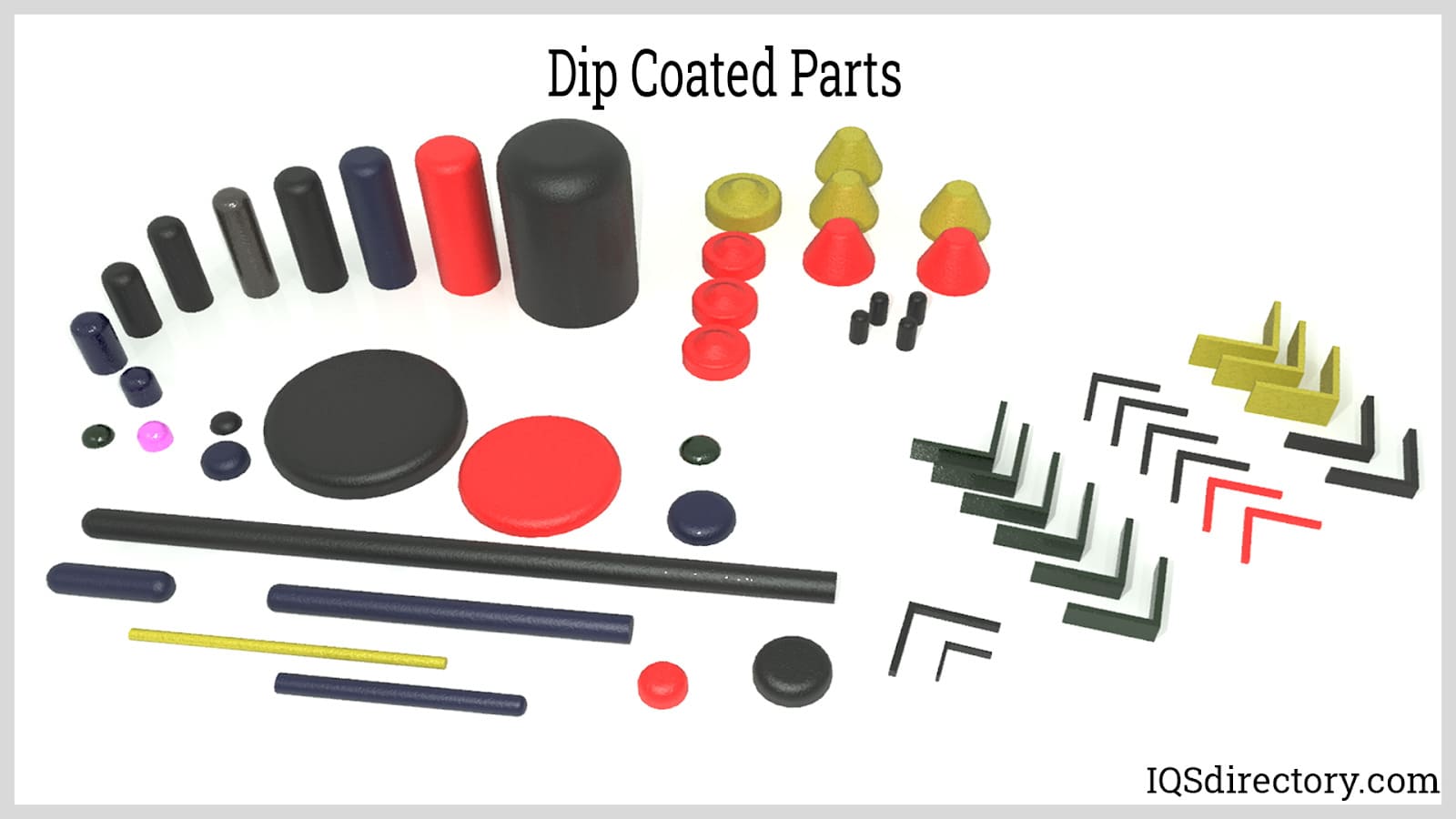

Plastic Blow Molding Plastic Dip Molding

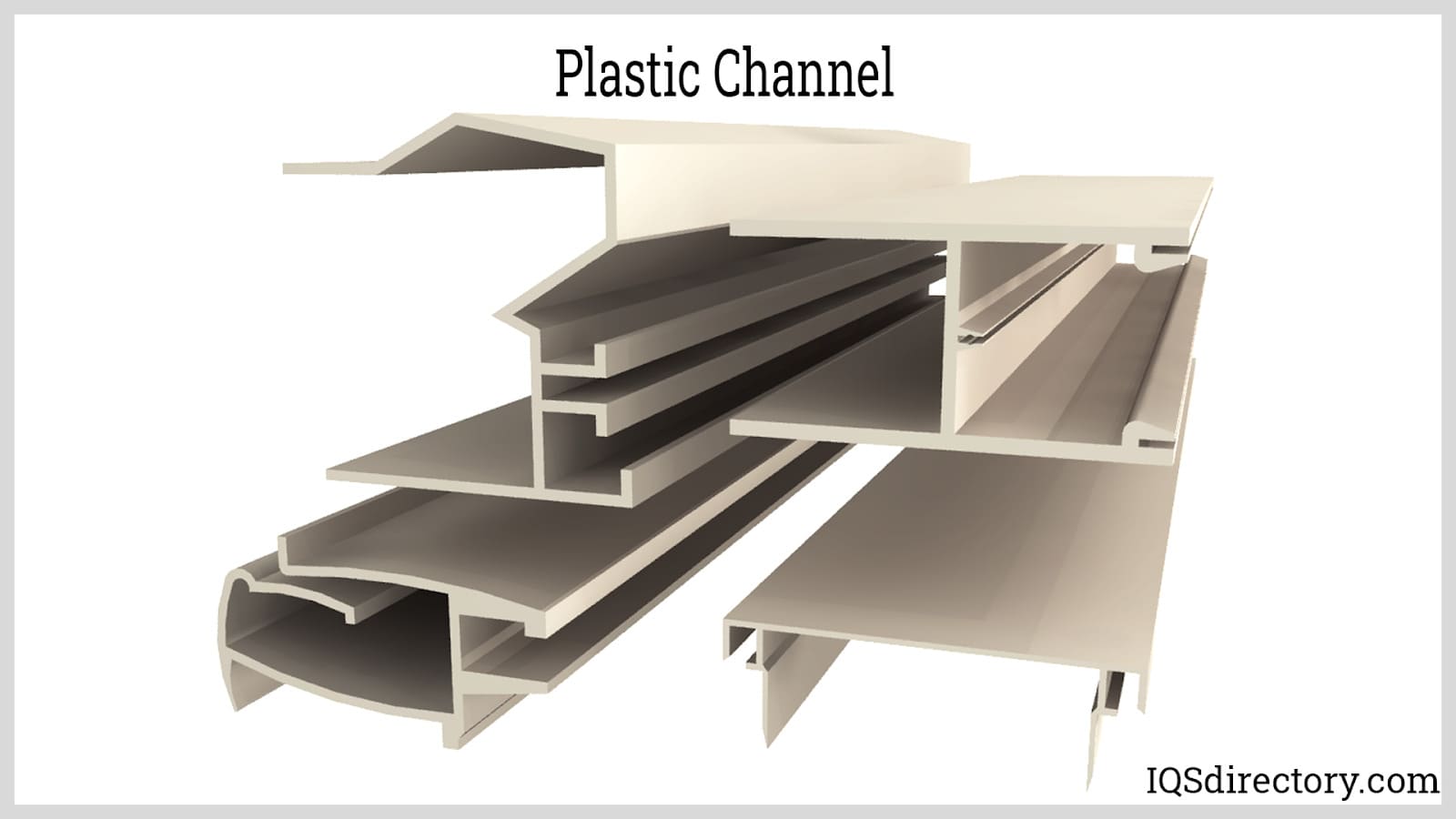

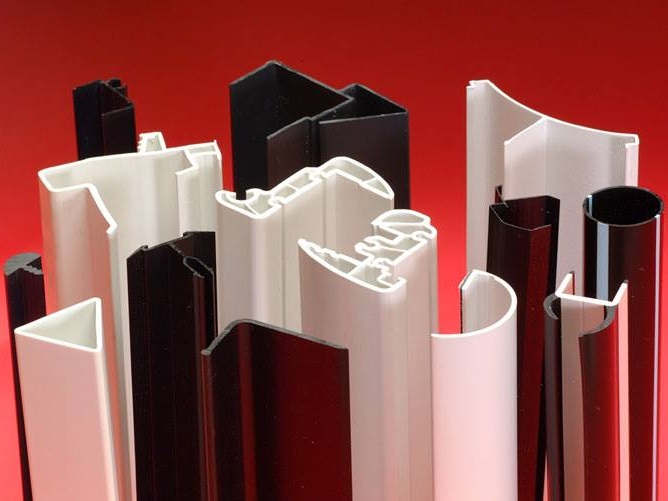

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services