Foam is defined as a substance that consists of countless little air bubbles trapped in a solid or liquid state. Foam fabricating is the process of converting polymer foam, a material that is versatile and lightweight. In general, during foam fabrication, foam fabricators melt the material down, froth it up, then cool it. This process fills the material with little bubbles and gives it its sponge-like appearance. Read More...

American Excelsior Company open_in_new

Location: Arlington, TX

Locations in OH, TX, IL, WI, WA - 800-777-7645

The applications for foam fabricating are only limited by one’s imagination; that is our slogan at American Excelsior. We are a foam supplier who offers many different foam cushions & foam padding for over a dozen industries. We offer foam materials like polyurethane foam, polyethylene foam & closed-cell foam; & services such as CNC foam cutting. Let us take your concept & turn it to reality.

Flextech open_in_new

Location: St. Louis Park, MN

Since 1992, Flextech has delivered innovative, custom engineered foam solutions. We combine our engineering and design services with our unique foam lamination, fabrication, and thermoforming capabilities, to provide quality foam components to a diverse customer base. Our customers include OEM’s in the medical, industrial, military, aerospace and consumer products markets. We invite you to connect and collaborate with our sales and engineering team. Let us show you the Flextech advantage!

Deluxe Packaging, Inc. open_in_new

Location: Pennsauken, NJ

Deluxe Packaging works hard to always create cost-effective solutions and services for our clients better than anyone else. We offer a full array of high quality products, including polyurethane foam, polystyrene foam, and polyethylene foam. Our products are customizable to match a product’s fragility and size. Deluxe Packaging is your complete packaging solution provider for all of your packaging needs.

Thrust Industries open_in_new

Location: Evansville, IN

Here at Thrust Industries we provide die cut foam that comes in a variety of shapes and configurations. We die cut foam from a number of materials including: urethane, PVC, polyester, neoprene, ether, cellular, volara, and much more. If you would like customized die cut foam then please give us a call today!

The term “foam fabricating” can also be used to describe the types of foam and the various uses and products that can be made from them.

Applications

Foam fabrication creates products and materials that provide services like insulation, sealing, liquid absorption, vibration dampening, cushioning, protecting, soundproofing, filtering and providing structure.

Fabricated foam is used across a wide range of industries, such as furniture, electronics, automotive, construction, healthcare, household, acoustics, and filtration. It is also used on oil rigs, satellites, and in weather balloons.

Products Produced

Foam Products

Foam fabricating services create a variety of foam types for a multitude of applications.

Open cell foams are flexible foam products with cells that permit air flow.

Closed-cell foams have dense cells that are isolated from one another. They do not permit air flow.

Acoustic foams are attenuated or non-attenuated flexible foams that absorb or shape sound, respectively.

Packaging foams are any foams used for product packaging and shipping.

Bonded foams are foam products that are made when fabricators glue shredded foam or foam particles together into a block. Bonded foams are most often used as carpet cushioning.

Flexible foams have a certain amount of give and are usually used in bedding and furniture.

Adhesive-backed foams allow users to hold foam padding in place. It also maintains steady, uniform pressure. Adhesive-backed foams are popular in medicine.

Cushion foams provide cushion to both furniture and athletic gear.

Molded foam is cellular foam that maintains its shape. If it has enough give to compress with pressure, it will return to its original mold shape when you remove the pressure.

Rigid foam is moisture resistant and heat resistant closed-cell foam.

Products Made from Foam Products

Examples of products made from polyurethane foam include insulated containers, flexible foam seating, protective foam padding, insulation foam, EKG pads, x-ray positioning pads, and surgical scrubbers.

Examples of polyethylene foam products include bracing and cushioning material. Material like this is used in handling, packaging and shipping items such as clothing, food, sporting goods, signs, furniture, and computer parts.

Examples of other foam fabricated products include gaskets, pillar stuffers, couch cushions, insulation, padding foam in slippers, sponges, insulation foam, mats, filters, orthopedic foam inserts, NVH seals, filter foam in AC units, memory foam mattresses, and memory foam pillows.

History

People began fabricating foam and foam products between the 1920s and 1930s, after they learned how to fabricate latex foam. The first two methods for creating polymeric foams were the Talalay process and the Dunlop process. The Talalay process was originally developed in the 1930s by the Talalay brothers, Joseph, Leon, and Anselm. Joseph Talalay later went on to form Vita Talalay, a company based in the Netherlands, with plants in the US, UK, and Canada. The Dunlop process was patented by Dunlop Rubber Company in 1929.

With these developments, companies around the world were free to pursue the creation of rubber foams for an ever-expanding list of applications. Part of the reason the foam fabrication applications spread so rapidly in the mid-20th century is the fact that, spurred on by demand during WWII, scientists were discovering and developing new rubber materials and chemicals every day. In 1947, for example, researchers at Dow Chemical invented Styrofoam, or foamed polystyrene.

Today, fabricators continue to fabricate foam for all kinds of applications. In recent years, they have made a number of breakthroughs, including the development of nanocellular polymer foams. One of the most pertinent focuses of our time is sustainability. To combat the potential environmental impact fabricating processes and foam scrap can create, fabricators have turned away from burning scrap and now reuse it or recycle it.

Materials

Fabricators can use a variety of materials to make foam. These include plastic, rubbers, and low-density elastomers like polyurethane, polyethylene, cross-linked polyethylene, polyether, PVC, and expanded polystyrene (ESP).

Plastics make foams with tiny, well-dispersed gas bubbles. Plastic foam is light with a high strength-to-weight ratio.

Polyurethane foam is the most commonly used. It is a durable closed-cell foam that can biodegrade in both indirect and direct sunlight.

Polyethylene is the most common foam fabricating material. Polyethylene foam is flexible, shock-absorbent, vibration dampening, and insulative. Fabricators extrude the expanded, closed-cell plastic foam mostly as a protective material.

One particular type of polyethylene foam is known as Ethafoam, which has exceptional shock absorption qualities.

Cross-linked polyethylene, or XLPE, is chemically and physically resistant. As a foam, it is smooth, thick and extremely fine celled.

Polyether foam is a low cost closed-cell foam with adequate acoustic and packaging properties.

PVC, or vinyl is self-extinguishing, moisture resistant and rot-proof. It creates a soft, pliable and closed-cell foam that bonds well with adhesives. It is used in gaskets in order to prevent water transmission.

Expanded polystyrene, or EPS, is used for diverse applications such as padding foam in slippers, insulation foam, oil rigs, filter foam in AC units, satellites, and weather balloons.

Process Details

1. Making the Foam

Fabricators typically form the foam by mixing polymers with a gassing agent and other chemicals. When they add the gassing agent, the material expands, forming a foam strip that is made up of countless gas bubbles within the material.

2. Forming the Foam Product

After making the foam, fabricators can put it through a variety of foam fabricating services such as foam cutting, die cutting, waterjet cutting, thermoforming, and foam felting.

Die cutting involves cutting different shapes out of foam strips, sheets, or blocks.

Water jet cutting fundamentally performs the same function but utilizes a high-pressure stream of water and is capable of cutting with more precision than die cutting.

Thermoforming is the most popular foam forming method. During this process, fabricators make machining shapes by heating the bulk foam materials.

Foam felting is another foam forming process during which fabricators compress and cure thick, soft foam materials in order to form denser foam materials.

3. Disposing Scrap

Certain parts of the foam fabrication process produce a lot of scrap, including during the die cutting process. During die cutting, foam scrap can be the result of changes in the converting process, the shutdown and startup of the production line or the material left over when shapes are die cutted. In addition, scrap happens when the useful life of foam products has expired.

So, after the foam fabricating process is done, fabricators need to dispose of the scrap. The preferred way to do this is via recycling.

Another way to dispose of foam scrap would be to burn it. However, this method has decreased in popularity over the past few decades. Although the U.S. government generally considers the burning of foam to be non-toxic, the increase of environmental concerns and stricter regulations regarding carbon dioxide emission have influenced companies to handle foam waste by way of recycling.

Design

When getting ready to fabricate a foam product, fabricators consider variables such as the type of material they will use, the fabricating processes they will use, product shape, product thickness, and standard requirements. One of the big decisions they make is whether they will create your product from closed-cell foam or open-cell foam.

Closed-cell foams contain foam cells which are sealed and separate from one another, or “closed.” Closed-cell foam has a high compressive strength and a high density. The cells expand when exposed to heated gas because the cells do not break, and liquid and gas molecules cannot freely travel from cell to cell. Since the expansion in the material is filled, closed-cell foam is an ideal material to use as a heat insulator.

Open-cell foam is lighter in weight, spongy, and soft. The surfaces of the bubbles, or the cell walls, are broken, and all the spaces in the material are filled with air. The soft, weak nature of open-cell foam makes the material ideal for foam cushions and foam padding. Open-cell foam is also twice as resistant to sound as its closed-cell counterpart and can thus be used as an effective sound barrier.

To make your product work better for you, foam fabricators can create a variety of custom foam products. To make custom products, fabricators use custom molds, custom materials, unique colors, and unique shapes and sizes. Learn more about what custom foam options particular foam fabricators offers by talking it over with a member of their staff.

Benefits

Foam fabricating is an advantageous process for a number of reasons. First, it is versatile. With it, fabricators can make foams with a vast array of qualities, from extreme stiffness to extreme pliability. In addition, foam fabricated parts are typically more lightweight than comparable products made via other forming processes. This is especially advantageous to customers with applications that benefit from lightweight parts, such as car fabricating. Another great thing about foam fabricating is the fact that it yields such good insulators, no matter the application. This is a huge benefit for applications related to acoustics, vibration or thermal insulation. Next, foam fabricating is economical, especially if you’re looking for products in bulk. This is true two times over, since fabricators can make use of scrap foam. Scrap foam can be rebounded, shredded, and reused for products such as carpet padding, or filler for pillows and other furniture. Recycling enables foam fabricating companies to recuperate the return on their investment, which would otherwise be lost if the scrap is burned.

Things to Consider

If you are interested in fabricated foam, you need to work with an experienced fabricator who can guide you through the process. Since foam fabricating is a popular process, there are a lot of companies out there who offer foam fabricating services. Unfortunately, they are not all of equal caliber and it’s easy to get overwhelmed. To help you on your way, we have put together a list of high quality, top rated fabricated foam product converters. You’ll find their information sandwiched in between these paragraphs. Before you start looking at them, we recommend you spend some time putting together a list of your own. This list should include your specifications, standard requirements, product request volume, budget, timeline, and preferred delivery style. Once you have put together your list, you can start browsing the fabricator websites we’ve provided. As you browse, compare their list of products and services to your specifications list. Pick three or four then reach out to them. Discuss your project at length, leaving no stone unturned. After you’ve spoken with each of them, decide which one can provide you with the best service, and get started. Good luck!

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

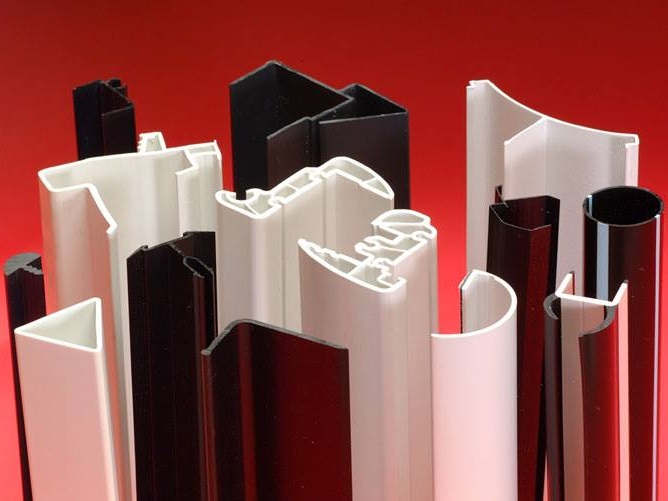

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services