FABEXCO

FABEXCORequest A Quote

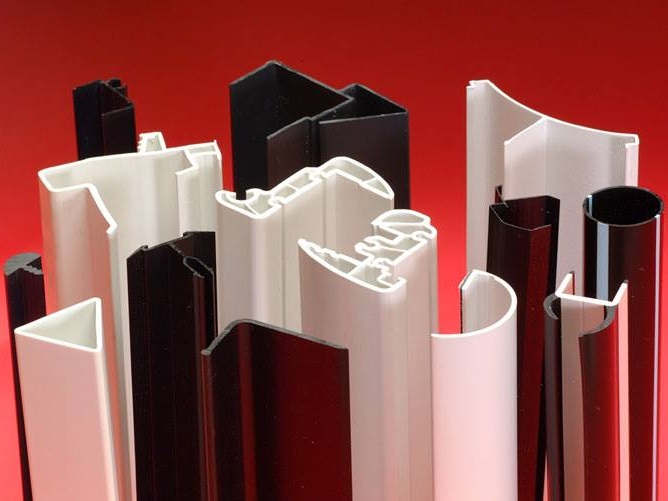

Modesto, CA | 209-529-9200At FABEXCO, we specialize in plastic extrusions. Our passion lies in crafting profiles that set us apart from the competition. We relish challenges and thrive on projects with unique specifications, tight deadlines, and unconventional requirements. Our commitment to excellence drives us to deliver results that others simply can't match. Our profile extrusion capabilities are vast and adaptable to meet your specific needs. Whether you require rigid, flexible, dual, or tri-profile extrusions, we have the expertise and technology to deliver. From crafting large to small shapes, we are equally comfortable handling high and low-volume production runs and quick-turn projects that require rapid results. When it comes to materials for profile extrusions, we've got you covered. We work with a diverse selection of materials to ensure that your project's unique needs are met. Our materials for profile extrusions include: Rigid PVC Flexible PVC Santoprene ABS HIPS HDPE Noryl PP TPU Acrylic Polycarbonate FABEXCO's commitment to quality, innovation, and customer satisfaction is unwavering. We are dedicated to pushing the boundaries of what's possible in plastic extrusion, and we welcome the opportunity to tackle even the most challenging projects.

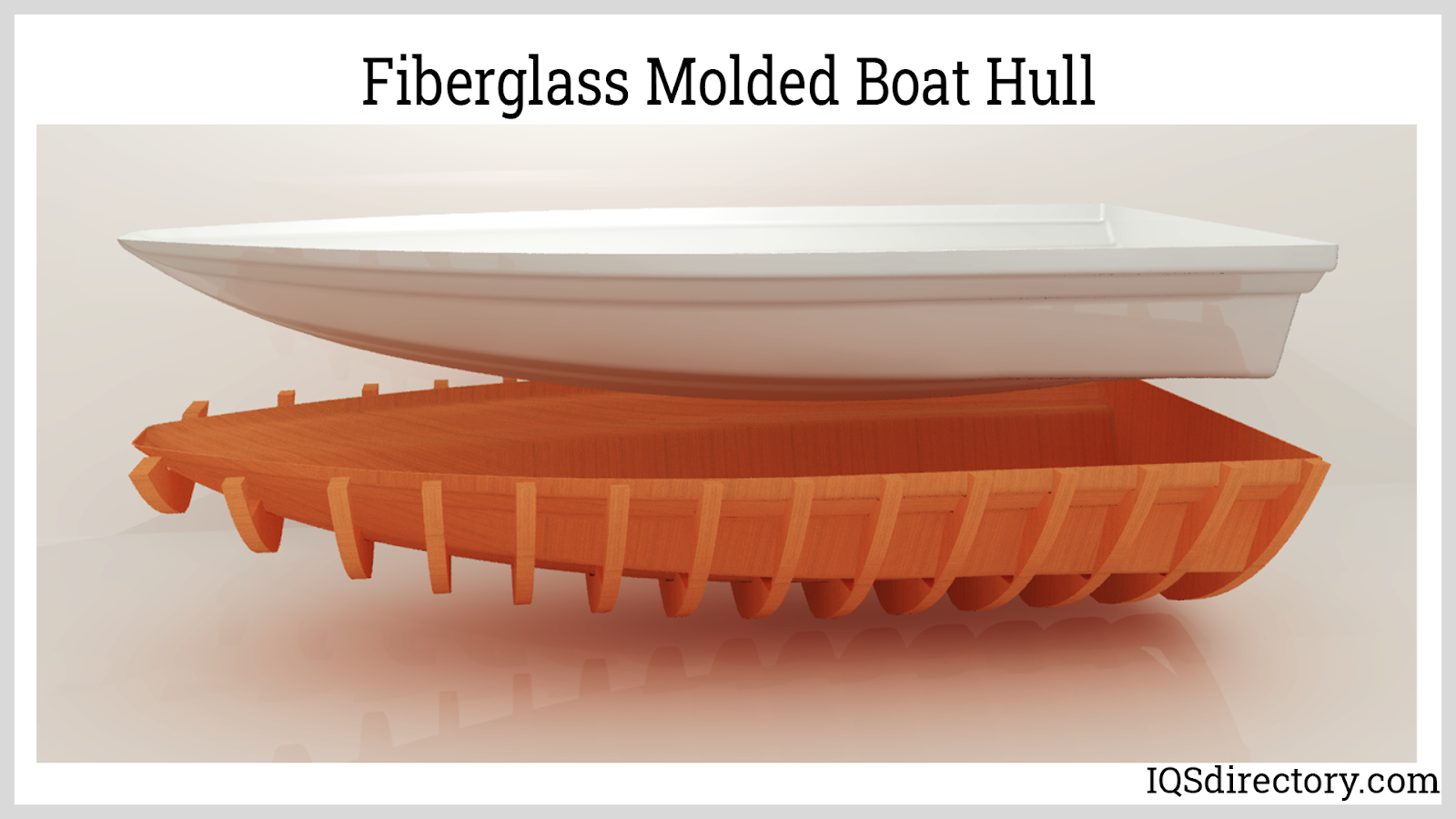

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

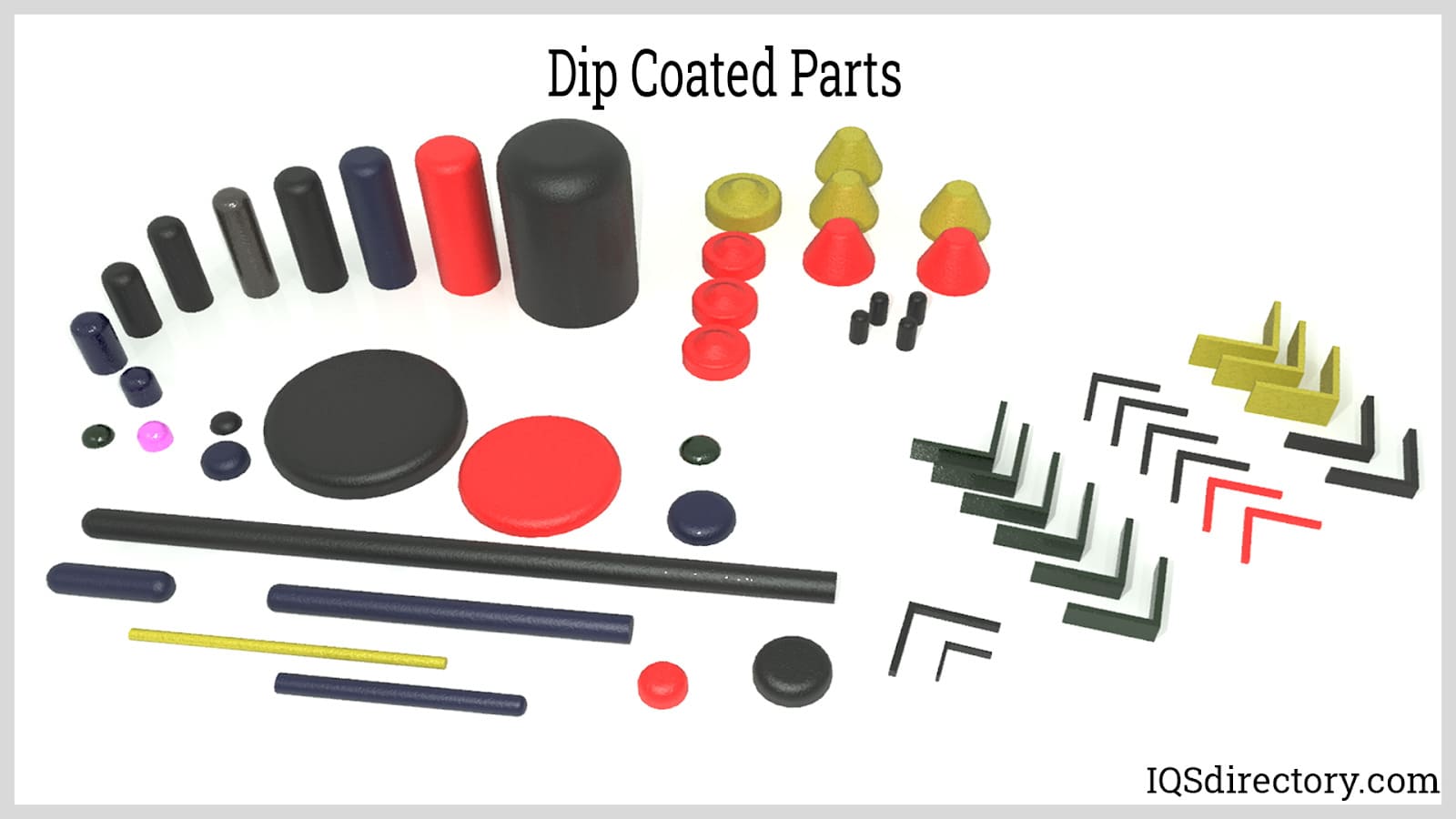

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

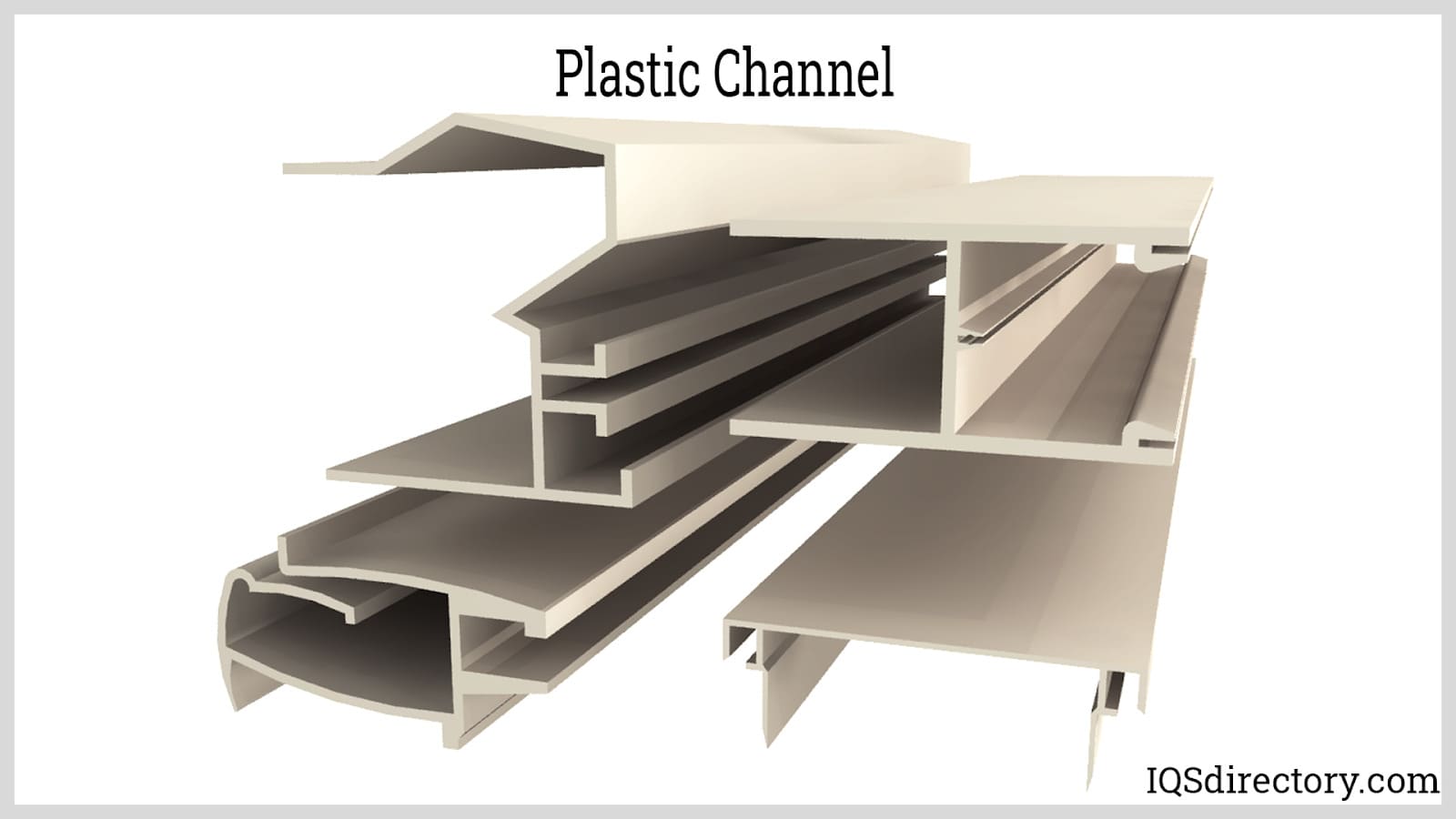

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services