Dimatic Die and Tool Co.

Dimatic Die and Tool Co.Request A Quote

Omaha, NE | 402-571-7300Dimatic Die and Tool Co., located in Omaha, NE, is a leading provider of injection molded plastics products and services. With a rich history spanning several decades, we have established a strong reputation for delivering high-quality solutions to our customers across various industries. At Dimatic Die and Tool Co., we specialize in the design, development, and manufacturing of precision injection molded plastics products. We have the expertise to produce custom injection molded plastic components that meet the unique requirements of our clients. Whether it's small intricate parts or complex assemblies, our team of skilled engineers and technicians collaborates closely with customers to deliver tailored solutions. We have established strong relationships with reliable suppliers to ensure a steady supply of high-quality raw materials. Our efficient supply chain management enables us to meet customer demands and delivery schedules. Dimatic Die and Tool Co. is committed to providing exceptional injection molded plastics products and services to our customers. With a focus on innovation, quality, and customer satisfaction, we strive to exceed expectations and build long-term partnerships. Our dedication to continuous improvement and technical expertise positions us as a trusted and reliable provider in the industry.

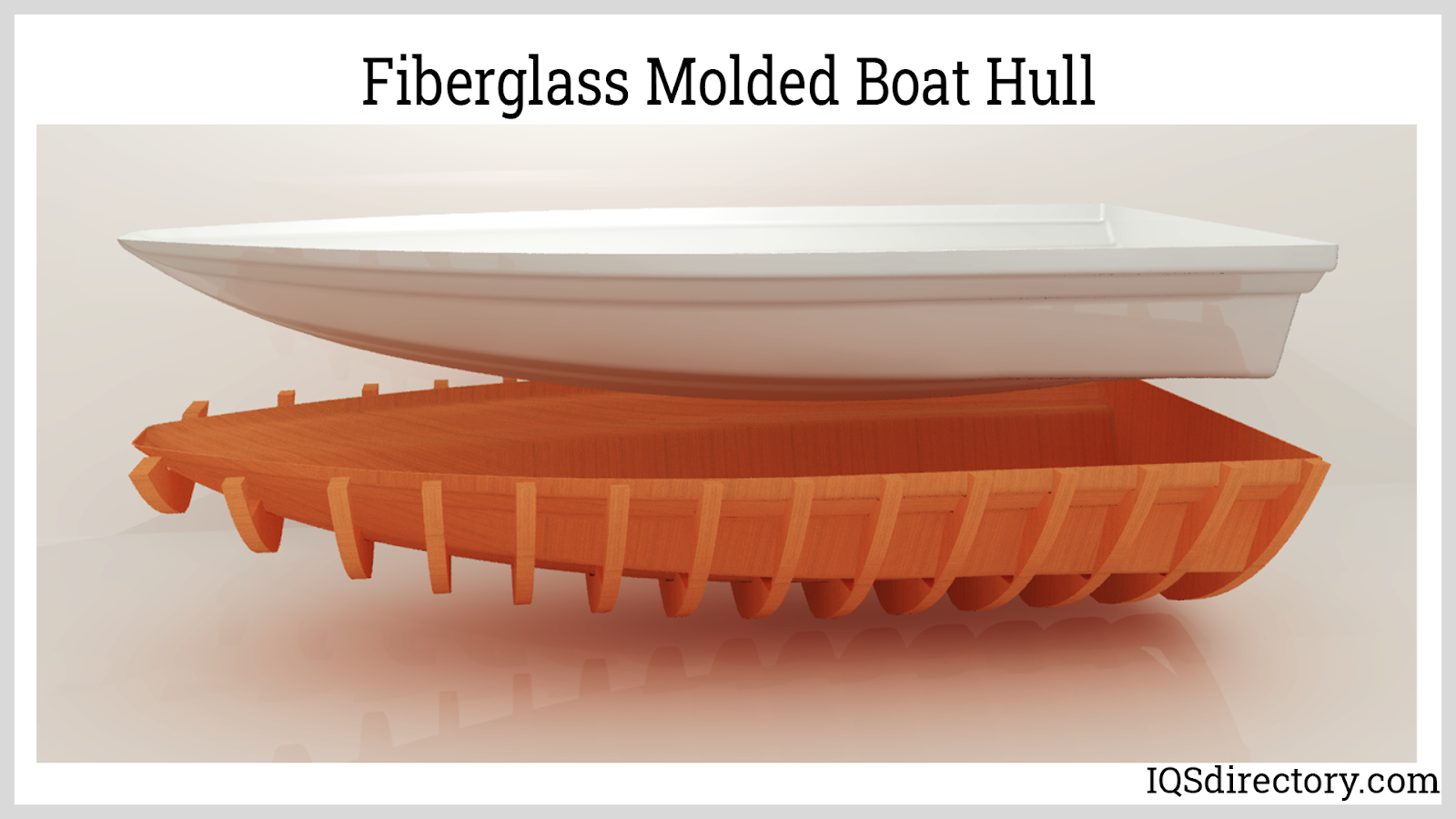

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

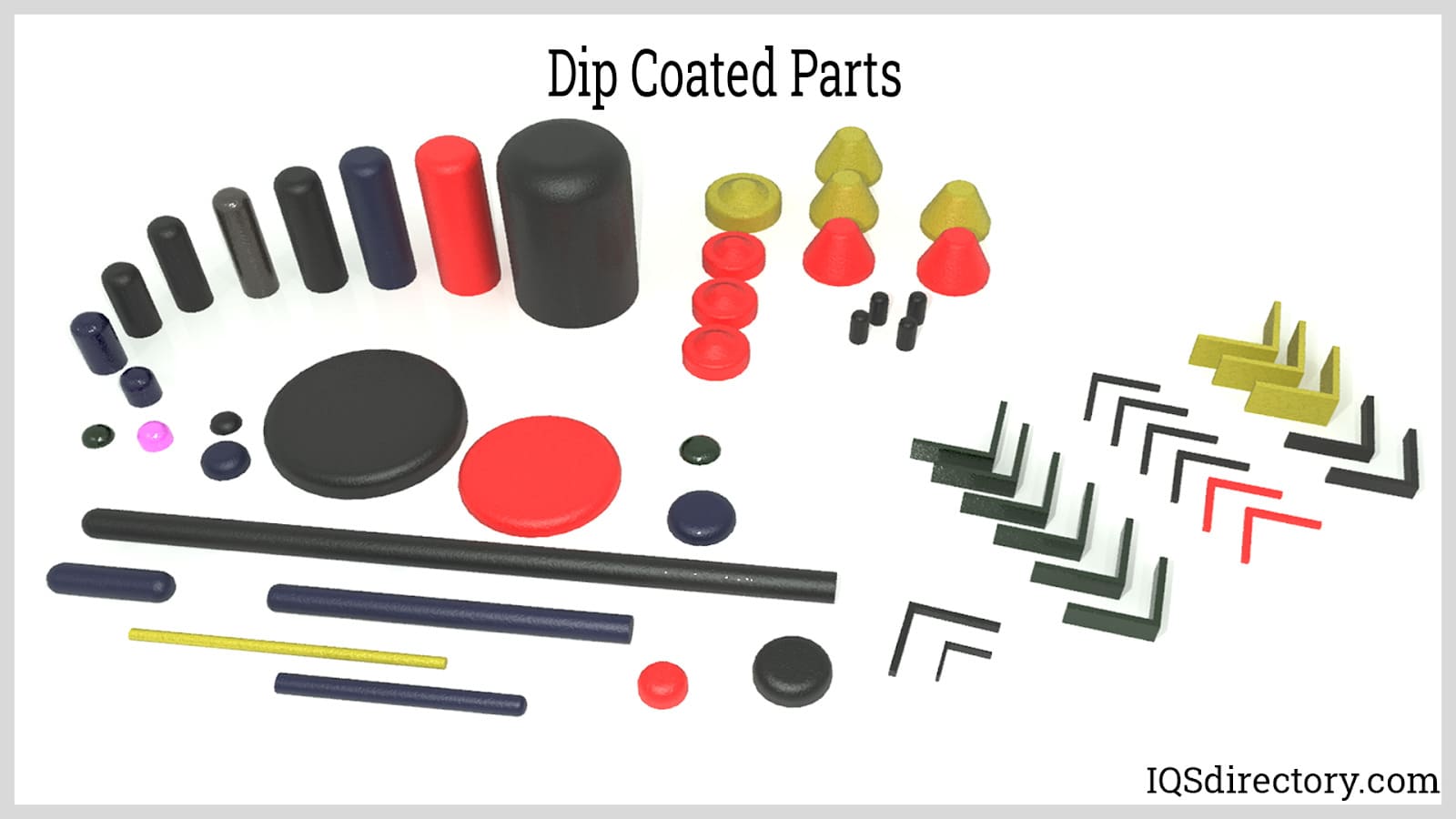

Plastic Blow Molding Plastic Dip Molding

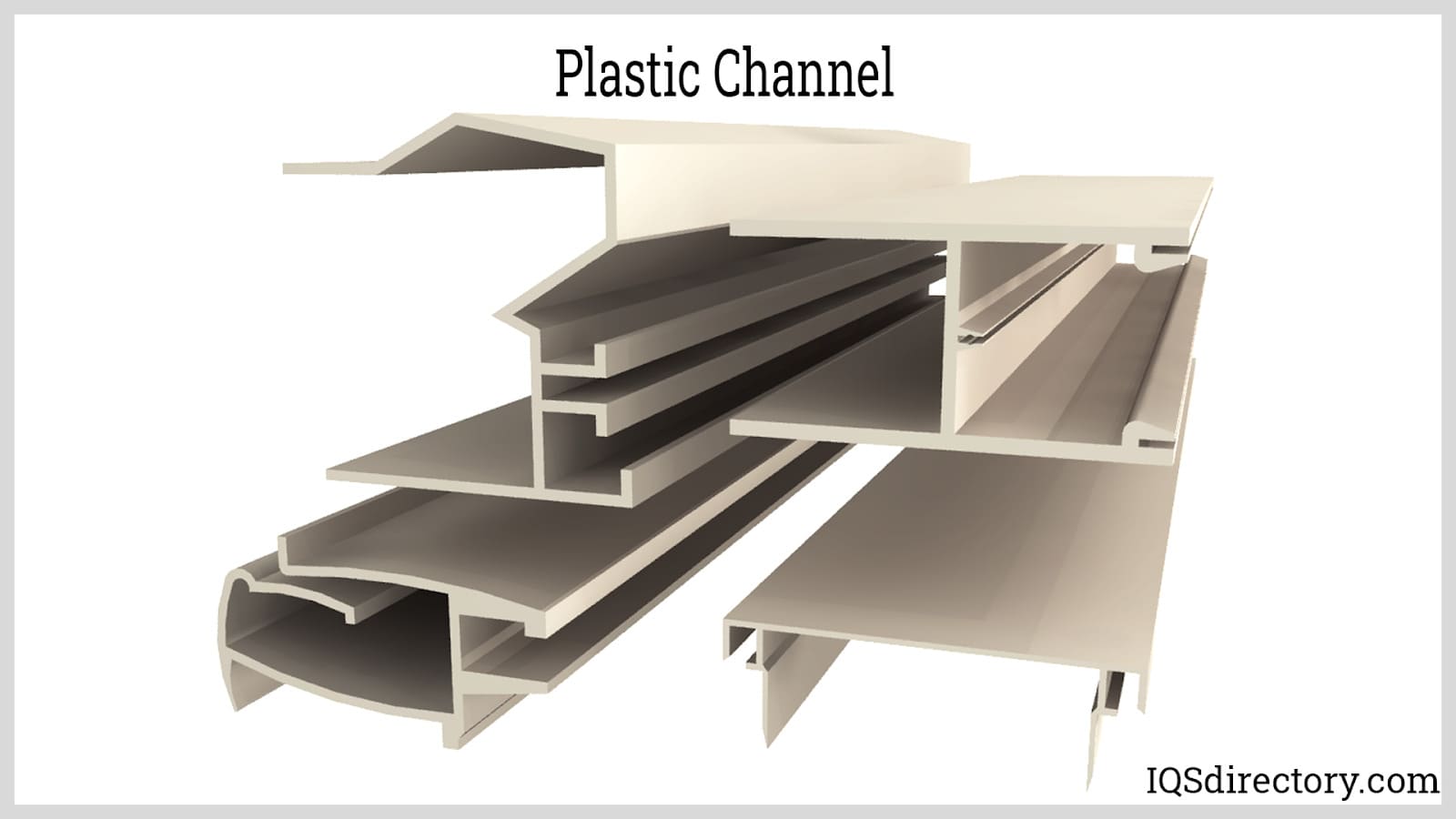

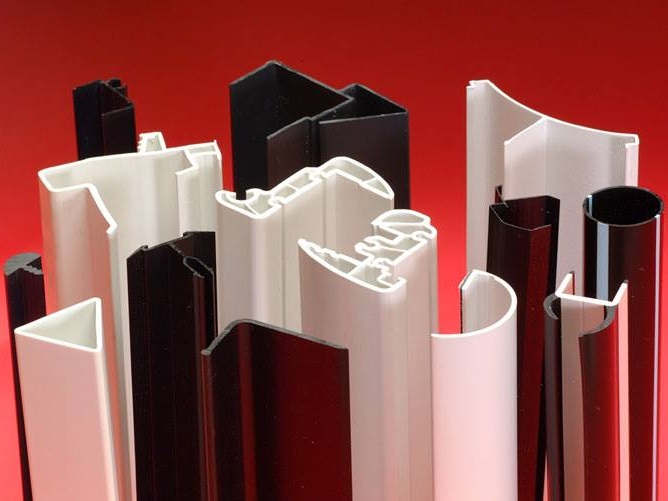

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services