Amcor Inc.

Amcor, Inc.Request A Quote

Thomson, GAAt Amcor, Inc., we are committed to providing high-quality injection molded plastic solutions that meet the diverse needs of our clients. Our expertise in precision molding allows us to create durable and reliable products tailored to the specific requirements of a wide range of industries. From concept to completion, we collaborate closely with our customers to ensure that every design is executed with exceptional craftsmanship and attention to detail. Our state-of-the-art facilities are equipped with advanced technology that enables us to deliver consistent results, no matter the scale or complexity of the project. Through our extensive capabilities, we offer comprehensive services that include product development, prototyping, and manufacturing. Our skilled team brings decades of experience to each project, ensuring that we remain at the forefront of innovation in the injection molding industry. By prioritizing quality, efficiency, and customer satisfaction, we have established ourselves as trusted partners for businesses seeking reliable plastic components.

More Plastic Molding Manufacturers

Additional Categories: Centrifugal Pumps

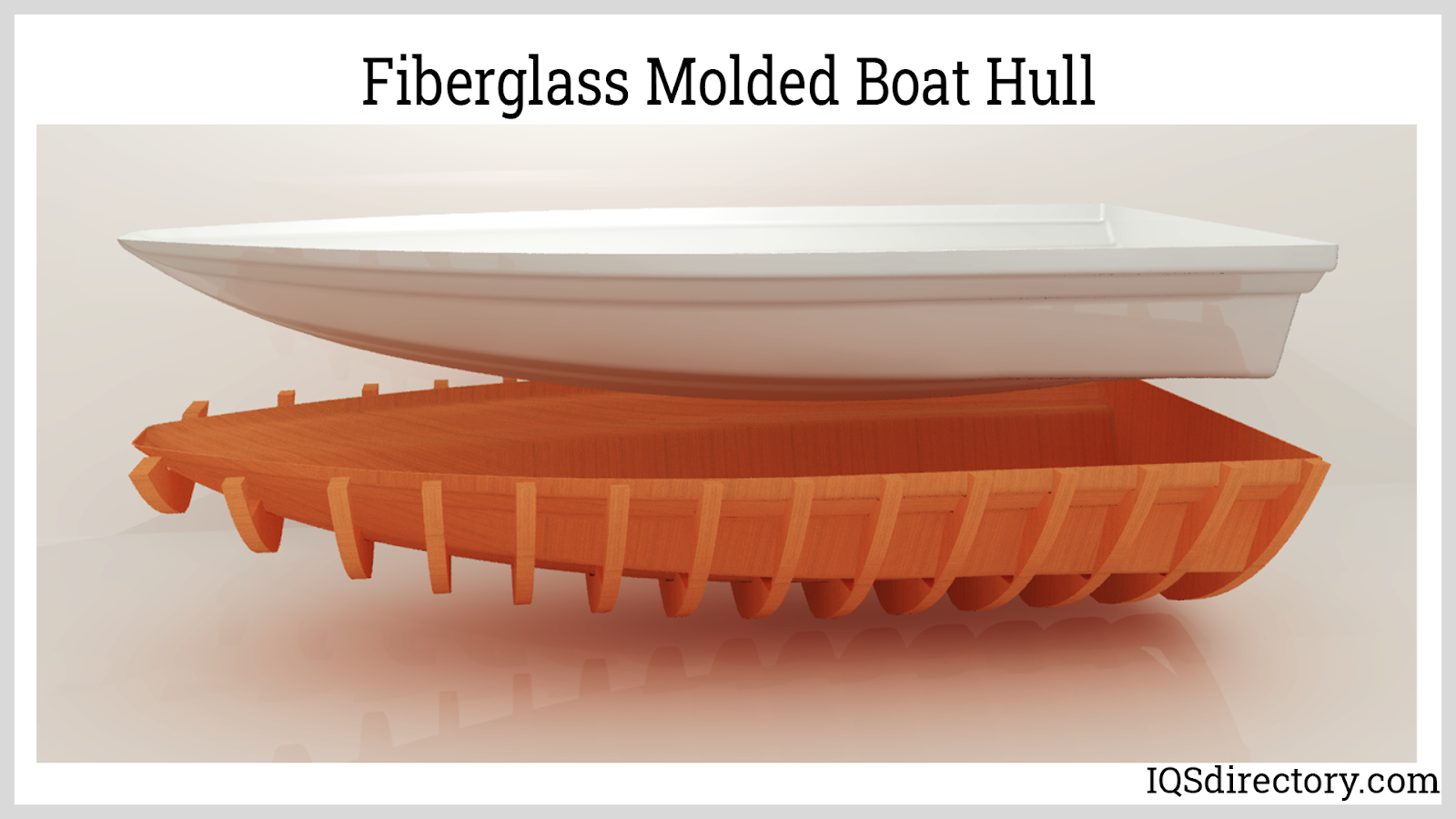

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

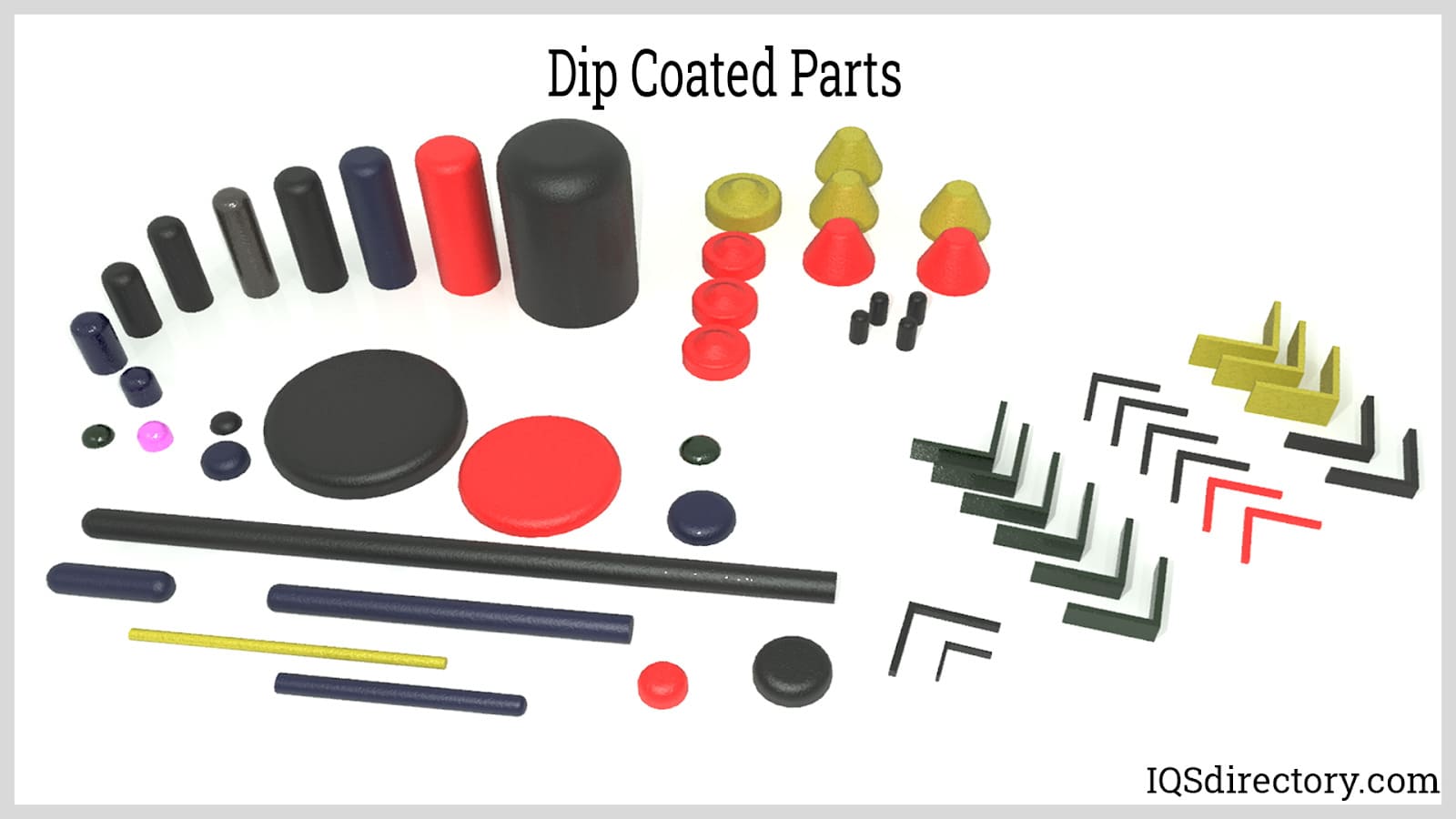

Plastic Blow Molding Plastic Dip Molding

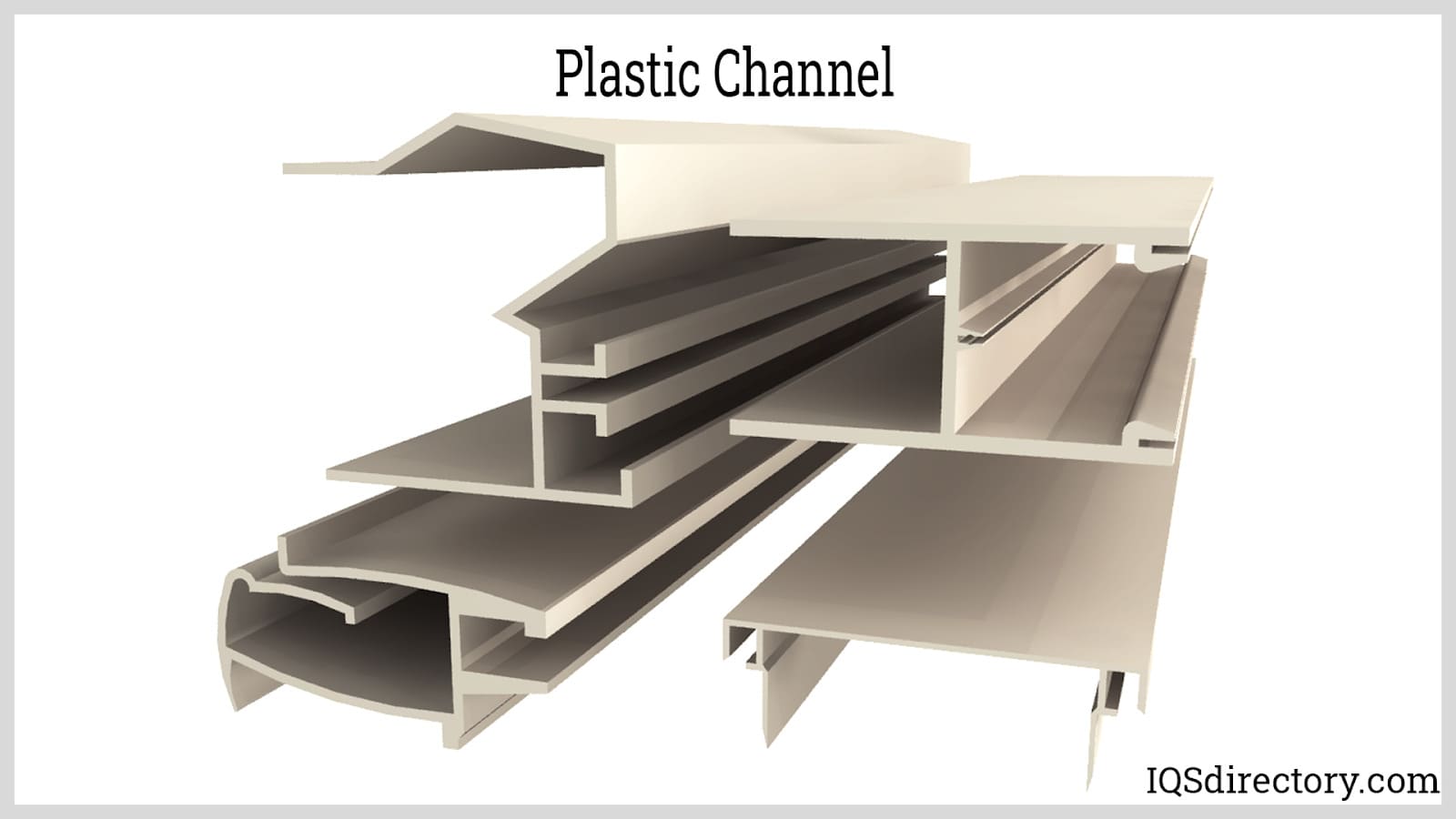

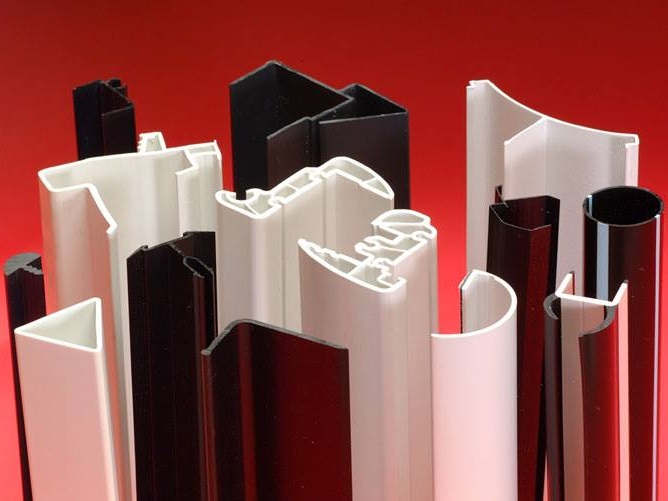

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services