Prime Manufacturing Technologies, Inc.

Prime Manufacturing Technologies, Inc.Request A Quote

Savage, MDAt Prime Manufacturing Technologies, Inc., we define ourselves as a committed partner in injection molded plastics, focused on delivering components that combine precision, durability, and consistent performance. We work with a broad range of thermoplastics and engineered resins to create parts that meet demanding structural, cosmetic, and functional requirements. By investing in advanced molding technology and maintaining strict process control, we ensure every component reflects the accuracy, repeatability, and clean finishes our customers rely on for high-performing assemblies and finished products. We approach each project with an engineering-driven mindset, collaborating closely with customers to refine part designs, select appropriate materials, and develop manufacturing strategies that balance performance with cost efficiency. Our expertise in mold design, tooling construction, and resin behavior allows us to guide customers from prototype development through full-scale production. Beyond molding, we support our customers with secondary operations, finishing, assembly, and value-added services that streamline the production process and reduce the need for multiple suppliers.

More Plastic Molding Manufacturers

Additional Categories: Wire Forms

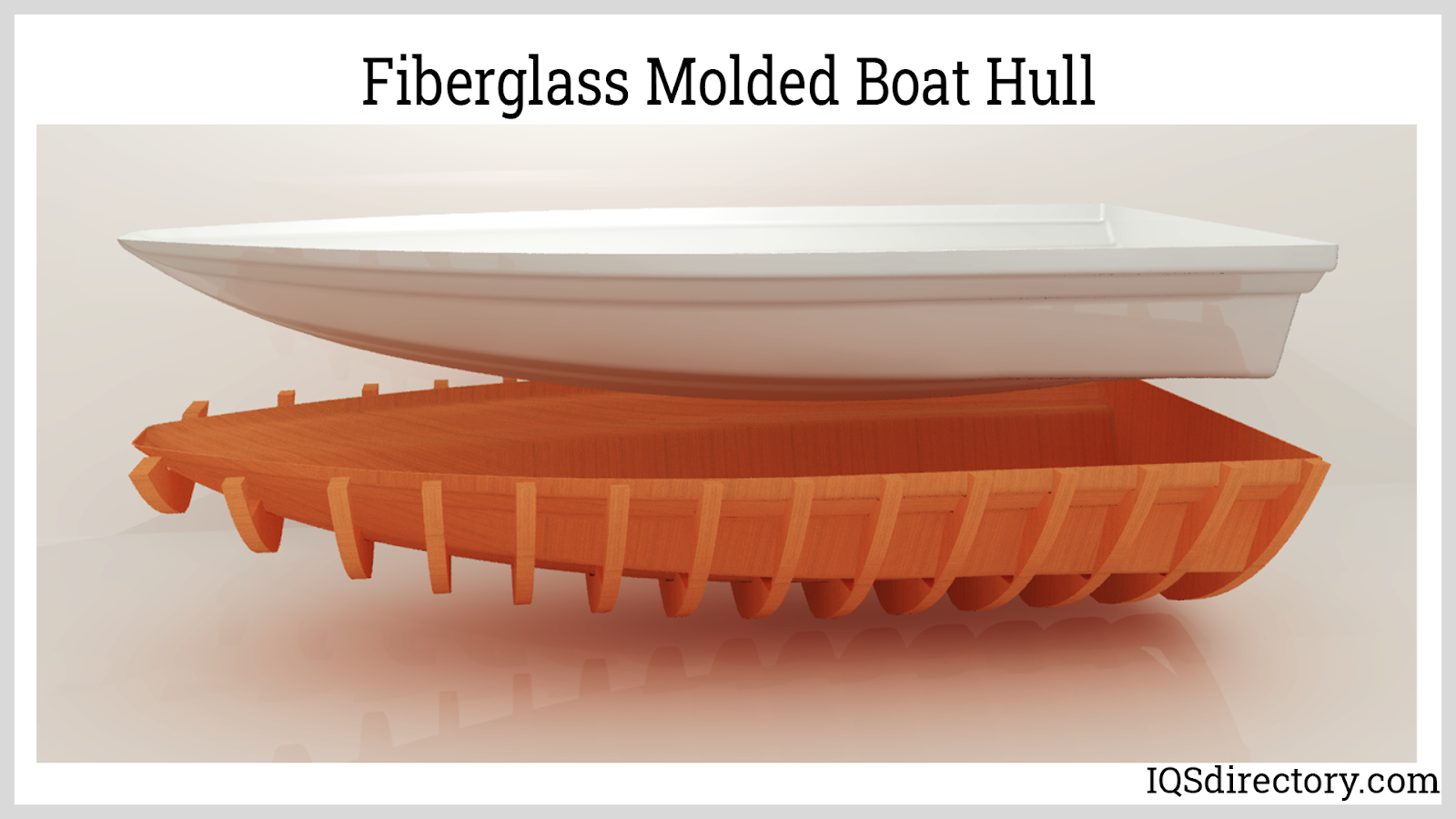

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

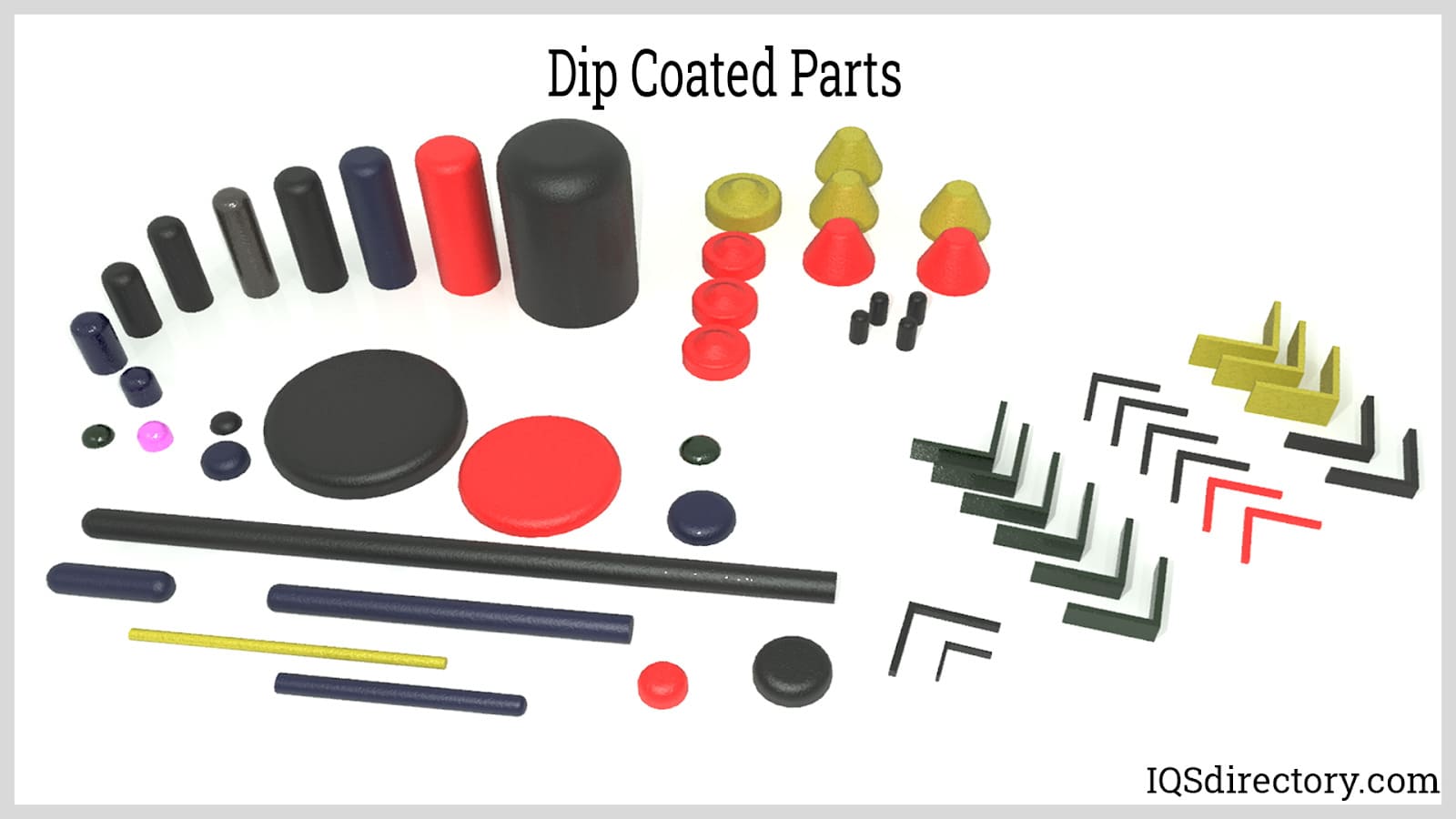

Plastic Blow Molding Plastic Dip Molding

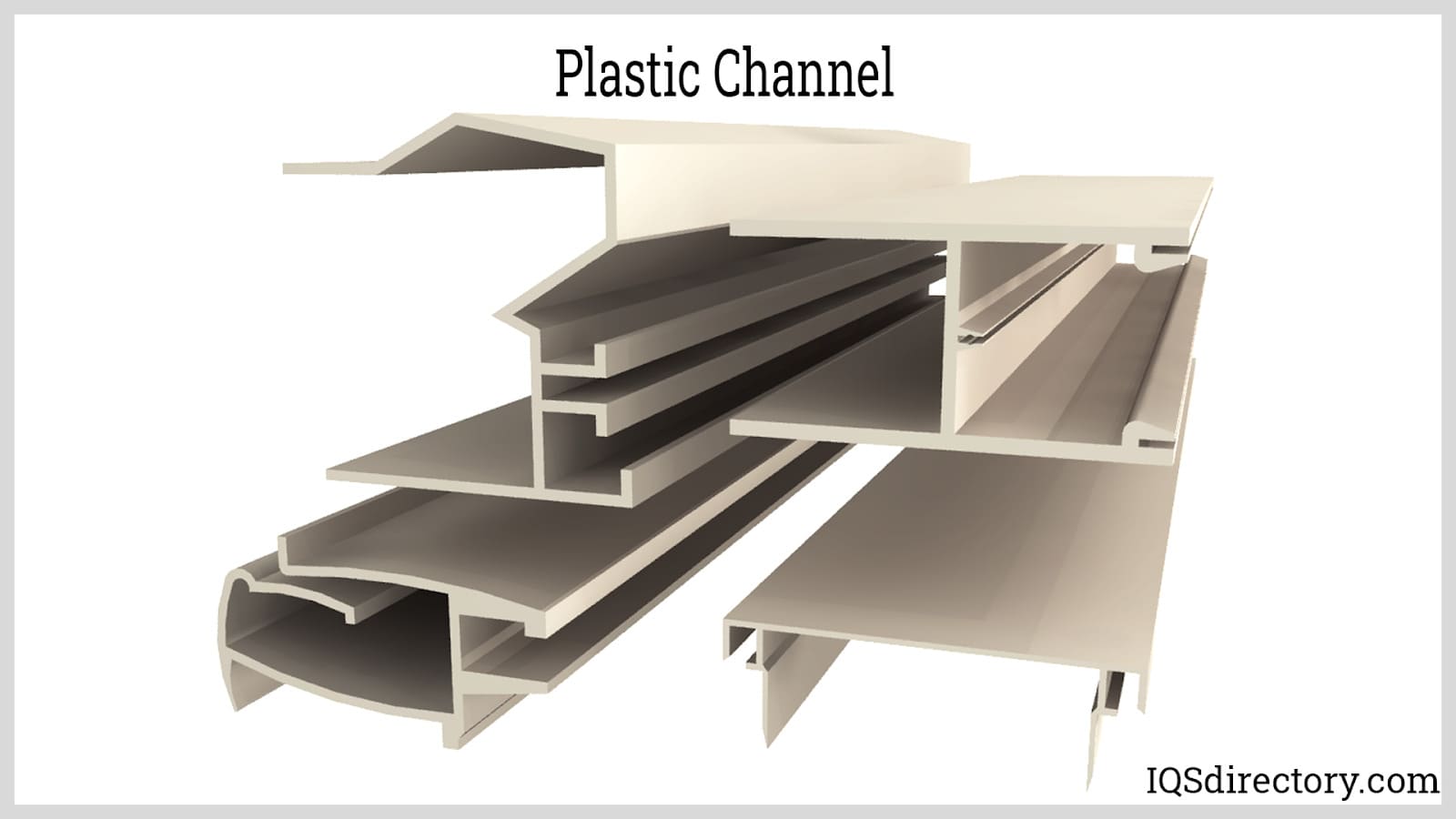

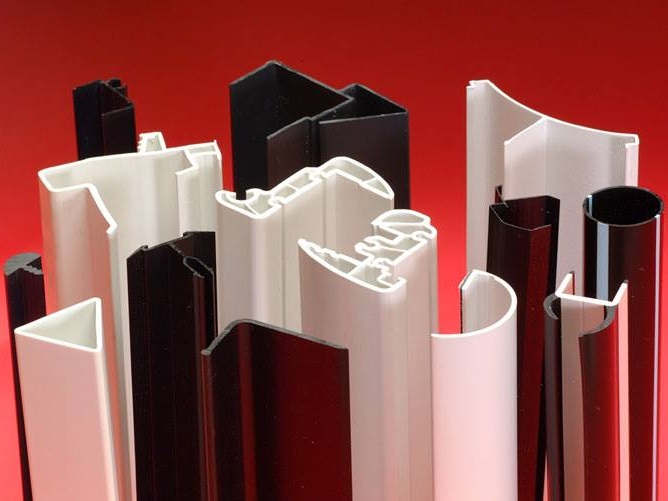

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotationally Molded Plastics

Rotationally Molded Plastics Vacuum Formed Plastics

Vacuum Formed Plastics Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services